Electromagnetically actuated clutches and brakes, clutch/brake combined units and tooth clutches

Thanks to the many design variations, Ortlinghaus electromagnetic clutches and brakes can be used in many different applications. The electromagnet with its built in coil is an actuation unit that is totally free of wear. The operating voltage, normally 24V DC, can usually be made available and introduced into the clutch or brake without any problem.

Thanks to the many design variations, Ortlinghaus electromagnetic clutches and brakes can be used in many different applications. The electromagnet with its built in coil is an actuation unit that is totally free of wear. The operating voltage, normally 24V DC, can usually be made available and introduced into the clutch or brake without any problem.

The engagement, or disengagement, can be adjusted and controlled electrically. The areas of application of this product group are indicated with the aid of a number of examples. You will find further details in the sections describing the individual products.

Multi-plate electric clutches and brakes are used in the main and secondary drives of machine tools, speed change gearboxes and in general mechanical engineering.

Single face electric clutches and brakes, combined units are used in secondary drives, for example, on the front power take off shafts of agricultural tractors. In addition they are frequently used in packing, textile machines, and on conveyor belts. The product range gives the development engineer the freedom to tackle an almost unlimited range of applications.

Electric Tooth clutches are the preferred clutch for printing machines; in addition they are used in, for example, turnstiles at public entrances and on drives for gates.

Spring-applied multi-plate brakes are used as safety brakes on, for example, cranes, winches and other lifting devices.

Spring-applied twin face brakes are used primarily for flanging directly onto electric motors.

Stationary field Sinus® multi-plate clutches for wet-running with flux through the plates design.

Multi-plate electric clutches and brakes

Single face electric clutches and brakes, combined units

Series 0-008-10./-30. and 0-009 Electromagnetic Brakes & Clutches

Magnetically actuated, rapid switching dry-running clutches and electromagnetic brakes for machines and many other devices. Both the clutches and the brakes permit space saving, adaptable to different design situations.

When disengaged, these electromagnetic clutches and brakes are free of residual torque. They can be supplied either with magnet bodies in a mounted version with bearings or flange fixings to the machine frame. In the case of the brakes the magnet body also forms the pole friction surface, giving an especially short overall length. The armature plate can be connected to the relevant rotors in many different ways.

Power feed: Via cables to the non-rotating magnet body.

Single face clutch/brake combined units

Series 0-008-102 and 0-081 Electromagnetic Brakes & Clutches

Supplied ready to install, these space saving combined units of electric clutch and brake, series 0-008 and 0-009, offer all the advantages of this type of design. These combined units have proved themselves especially suitable for drives in which the sequence of clutch disengagement/engagement and braking must be carried out continuously, rapidly and precisely. In addition to an open version (0-008-102), a unit in a closed housing is also available (0-081). The latter permits foot mounting and connection via shaft journals.

Power feed: With 0-008-102 via cables to the non rotating magnet body; with 0-081 to a terminal box on the housing.

Tooth clutches with and without slipring for wet- and dry-running

Electric Tooth Clutches

Series 0-012 and 0-013 Electromagnetic Brakes & Clutches

Non-slip, compact clutches with teeth for the transmission of high torques in small spaces. This type of electric clutch is the correct choice when static engagement only, is required. Engaging at low speeds can also be carried out subject to particular electrical measures being taken. There is no residual torque when the clutch is disengaged.

Power feed: In the case of 0-012 via slipring and brushes. In the case of 0-013 via cables and rectangular connectors.

Spring-applied multi-plate brake for wet- or dry-running

Spring-applied multi-plate brakes

Series 0-028 and 0-228 Electromagnetic Brakes & Clutches

The dry-running version is an electromagnetically released multi-plate brake that can be mounted as required. Special options: Dust cover, closed plate chamber; manual release lever for emergencies; version for wet-running.

Friction combination: Steel/organic friction lining for dry-running or steel/brass for wet-running

Power feed: Either via cables and rectangular connectors (24 V DC) or to a connection box with integrated rectifier (220 V)

Spring-applied twin-face brakes for dry-running

Spring-applied twin face brakes

Series 0-207 Electromagnetic Brakes & Clutches

This brake is particularly suitable for mounting on electric motors.

In addition to the standard version, a central torque setting facility is available, together with dust protection and manual release lever.

Friction lining: The single plate has organic friction linings on both sides.

Power feed: Via cables to the stationary magnet body.

Accessories for Electromagnetic Brakes & Clutches

A comprehensive range of accessories are available for operating and controlling brakes and clutches.

We can supply…

- Connection boxes

- Rectifiers

- Plug-in connections/plugs

- Electronic load relays

- Power feeds

- Capacitors

- Brush holders

- Varistors

Application Examples of Electromagnetic Brakes & Clutches

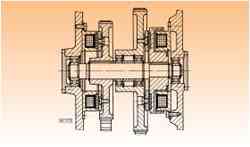

Electromagnetic single-face clutch, series 0-008-100, here in combination with an electromagnetic single-face brake, series 0-009-100.

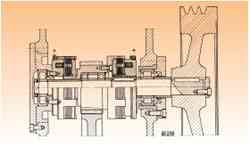

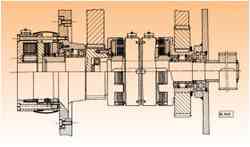

Electromagnetic Sinus® multi-plate clutch with slipring, series 0-011, and electromagnetic Sinus® multi-plate brake, series 0-011-300, as fitted in a straightening and cut-off machine.

Stationary field electromagnetic Sinus® multi-plate clutches. Series 0-010, friction combination steel/steel, here in combination with an electromagnetic, spring-applied multi-plate brake, series 0-028, friction combination steel/”Ortex” friction lining, as fitted in winch drives.

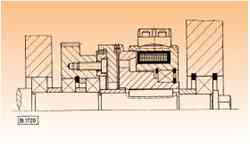

Stationary field electromagnetic tooth clutch, series 0-013 with the tooth wheel flanged onto the driving part.